Guangzhou Zaomi Cosmetics Technology Co., Ltd. (hereinafter referred to as Guangzhou Zaomi) was established in 2022 and is affiliated to Wesley Fine Chemical Group;

The products are developed and produced using the beauty product formulas and processes of France (ZAOMI) Zaomi Cosmetics Co., Ltd. It is a comprehensive enterprise integrating R&D, production and sales with spray beauty products as its core industry.

The Guangzhou Zaomi production base is located in the beautiful Yingde Wesley Industrial Park, with an area of about 100,000 square meters.

It has a research and development center, quality assurance center, production and manufacturing center, material control center, comprehensive office building, employee dormitory and

employee club, etc. The company currently has more than 350 employees, of which more than 60% have college or technical secondary school education.

The R&D center has more than 10 senior experts and senior engineers in the beauty industry at home and abroad, and is equipped with internationally advanced R&D and testing equipment, with strong R&D capabilities. The manufacturing center has a 1,500-square-meter GMP cosmetic aerosol production workshop, two 2,800-square-meter standard aerosol production workshops and two 1,000-square-meter cream and liquid filling production workshops, three cosmetic aerosol production lines, 16 fully automatic aerosol production lines, and eight cream and liquid filling production lines, with a daily production capacity of 500,000 bottles.

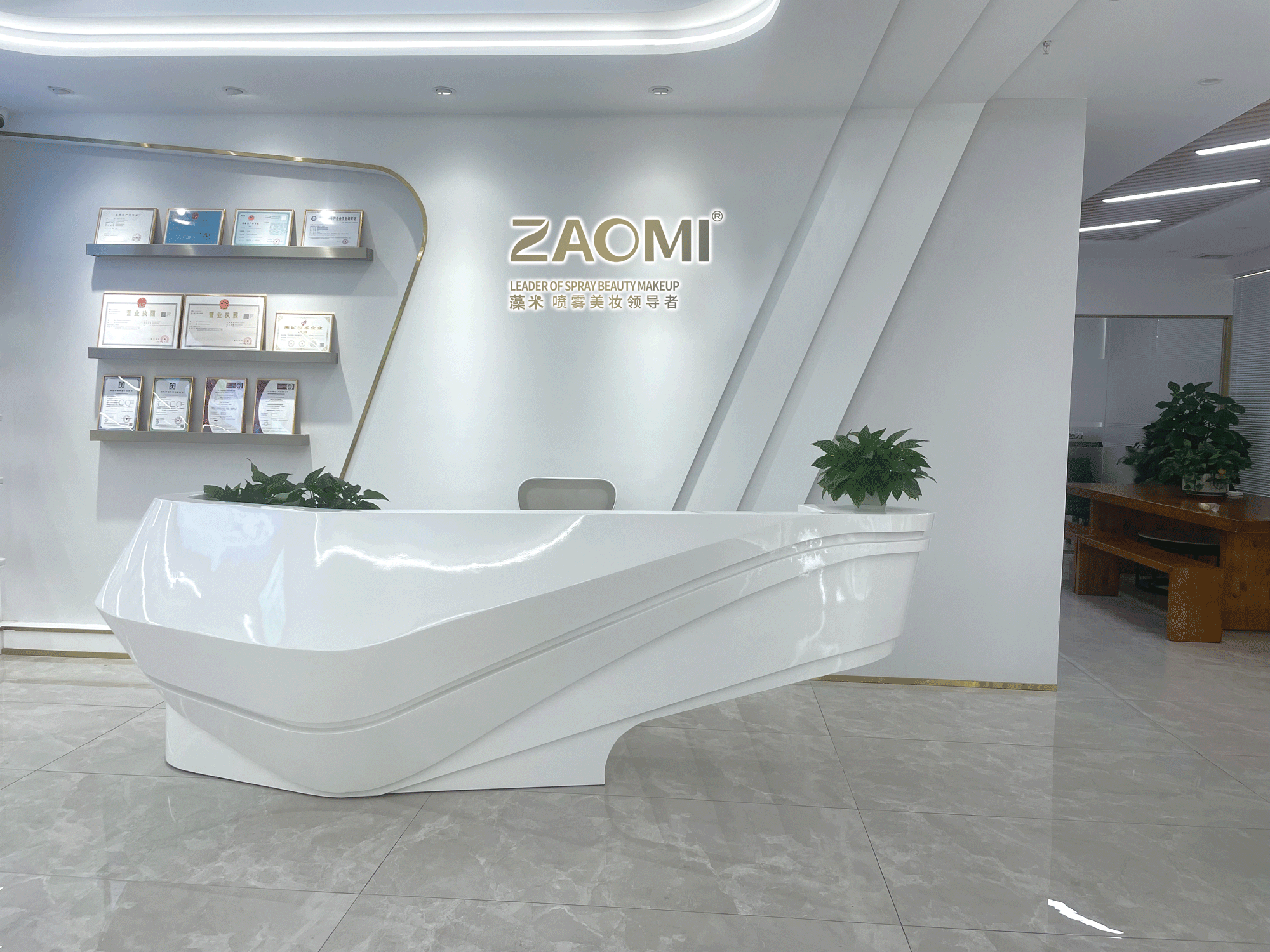

It has passed IS09001, IS014001, US FDA, European BSCI, Cosmetics GMP and other certifications, and obtained

"Dangerous Chemicals Safety Production License", "Cosmetics Production Hygiene License", "Special Cosmetics Production License",

"Disinfection Product Production Enterprise Hygiene License" and "National High-tech Enterprise, Guangdong Province Specialized and New Small and Medium Enterprises, Guangdong Province

Innovative Small and Medium Enterprises, Qingyuan Engineering Technology Research Center Enterprises" and other qualification certifications.